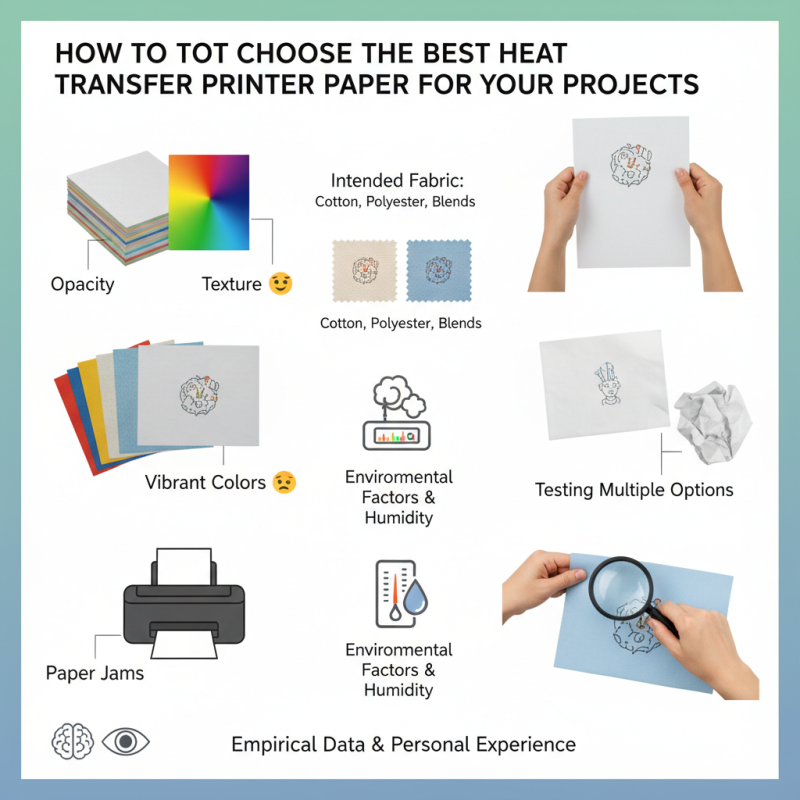

When selecting Heat Transfer Printer Paper, various factors come into play. The market for heat transfer printing has shown steady growth, with a projected CAGR of 5.4% from 2021 to 2028. Understanding the materials available is essential. Different papers offer unique qualities, such as opacity, texture, and durability.

Some brands boast vibrant colors and quick drying times. However, not all heat transfer papers are compatible with every printer. It's crucial to ensure the correct pairing. Many users report frustration due to paper jams or fading designs. These unforeseen issues can hinder project success and slow down creativity.

Choosing the right Heat Transfer Printer Paper also depends on the intended fabric. Cotton, polyester, and blends each react differently. Moreover, environmental factors like humidity can also affect outcomes. Therefore, testing multiple options before finalizing is advisable. Empirical data can provide guidance, but personal experience often reveals the most about a paper's performance.

Heat transfer printing is a fascinating process that combines art and technique. At its core, it involves transferring ink from paper to fabric using heat and pressure. Understanding the basic principles is essential. The type of paper chosen can significantly impact the final result. Not all paper interacts the same way with heat. Some papers produce vibrant colors while others may fade quickly.

When you apply heat, the ink sublimates and bonds with the fabric. This requires precise temperature control. If the heat is too high, the fabric may scorch. Too low, and the ink won’t adhere. Testing different temperatures can lead to surprising outcomes. Sometimes, the colors might not match your expectations. That’s okay; experimentation often yields the best results.

Choosing the right paper is not just about quality. It’s also about compatibility with your project. Different fabrics might require specific types of transfer paper. Cotton absorbs the ink differently than polyester. Recognizing these differences can improve your work. Mistakes might happen along the way, and that’s part of learning. Each failure can inform future choices.

| Paper Type | Material | Best For | Print Quality | Heat Resistance |

|---|---|---|---|---|

| Inkjet Transfer Paper | Polyester Coated | Light Fabrics | High | Medium |

| Laser Transfer Paper | Polymer Coated | Dark Fabrics | Excellent | High |

| Sublimation Paper | Dye-Sublimation | Polyester Fabrics | Very High | Very High |

| Photo Transfer Paper | Microporous | Photos and Images | High | Medium |

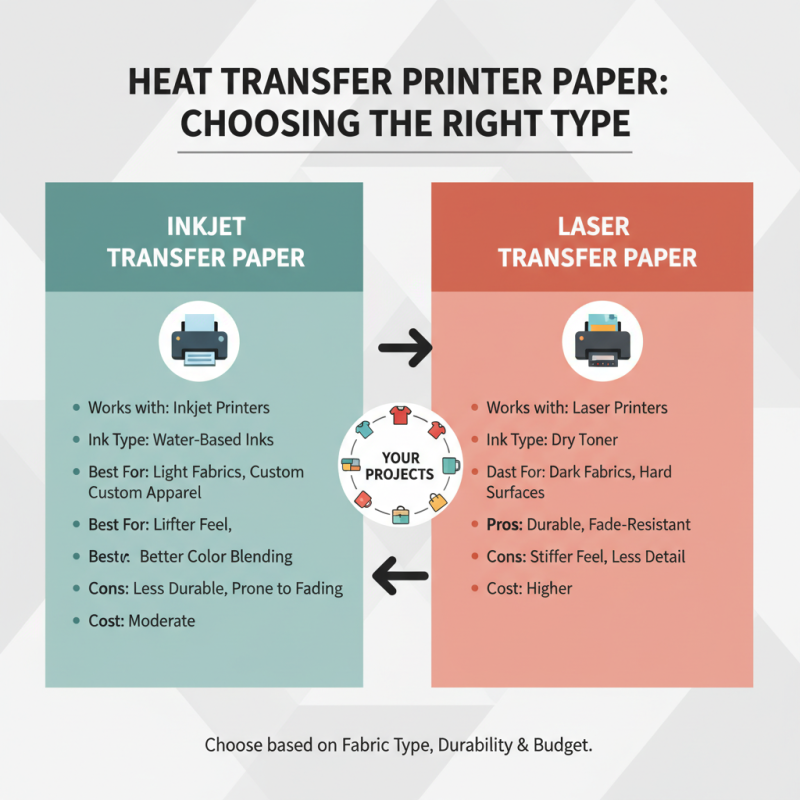

Choosing the right heat transfer printer paper can significantly affect your projects. Understanding the types available helps in making a better choice. Most commonly, there are two main types: inkjet and laser transfer papers. Inkjet papers work best with water-based inks, while laser papers are suited for toner. Each type has its unique features and costs.

Inkjet transfer papers are usually less expensive. They provide vibrant colors and high-quality prints. However, they can be challenging to work with. Inkjet prints may smudge or fade over time. Laser transfer papers, on the other hand, tend to be more durable. They produce sharp, long-lasting images. Yet, they are generally pricier. Sometimes, the higher cost may not justify the quality if you're on a budget.

Consider your specific project needs. For small, personal tasks, inexpensive options might suffice. Larger productions may demand higher quality papers despite the cost. Take the time to experiment. You might find that one type works better for the materials you're using. Don't hesitate to test different brands or styles. It's all part of the creative process.

Choosing the right heat transfer printer paper is crucial for achieving the best results on different fabrics. Various factors can affect the outcome. One important consideration is the type of fabric itself. Cotton, polyester, and blends each require specific kinds of transfer paper. For instance, dark fabrics need paper designed for vibrant colors to avoid dull results. Using the wrong paper can lead to unwanted fading or peeling.

Another key factor is the printing method. Inkjet and laser printers have different compatibility requirements. Certain transfer papers work well with inkjet printers, while others are intended for laser technology. It’s vital to check what your printer can handle. This oversight can ruin your project. Testing with smaller samples before committing to a larger batch is wise.

Finally, consider the intended purpose of your project. Will the item be washed frequently? If so, look for papers with high durability. Some options may crack or fade after a few washes. Always consider the end-use, as it will guide you towards the best choice. In the end, some trial and error may be necessary to find the perfect fit for your needs.

When choosing heat transfer printer paper, evaluating print quality is crucial. One key factor is ink compatibility. Different papers may react uniquely to inks. This could affect color vibrancy and durability. A paper that works well with one type of ink might not yield the same results with another. Experimentation is sometimes necessary. Test various combinations to find the best match.

Transfer efficiency data also plays a significant role. Some papers guarantee higher transfer rates, ensuring designs adhere effectively to various surfaces. However, not every paper lives up to its claims. Some transfers may appear faded or uneven. This unpredictability can be frustrating. It’s essential to look for papers that have reliable testing results available.

Pay attention to details in the transfer process. Adjust your printer settings based on the paper used. Sometimes even minor changes can lead to significant improvements. Compare multiple brands to see which ones deliver consistent results. Learning from each printing session is vital. Each step helps refine your technique and leads to better outcomes in your projects.

When selecting a heat transfer printer paper, cost-effectiveness is crucial. High-quality transfer papers might seem expensive initially. Yet, their long-term benefits can outweigh the cost. Cheaper options often lead to poor prints and wasted materials. This can be frustrating and costly in the long run.

Investing in quality also means better durability. Images printed with high-quality papers tend to last longer. They resist fading and cracking over time. This is particularly important for projects that require longevity. You can achieve stunning results with vibrant colors and sharp details, enhancing the overall value of your work.

However, it’s essential to consider your specific needs. Not every project will require the best paper. Sometimes, the mid-range options can serve well without breaking the bank. Reflecting on past experiences, you may find that some papers did not meet expectations. Balancing quality with budget constraints requires attention. Identifying what works best for your projects can lead to better decisions in the future.